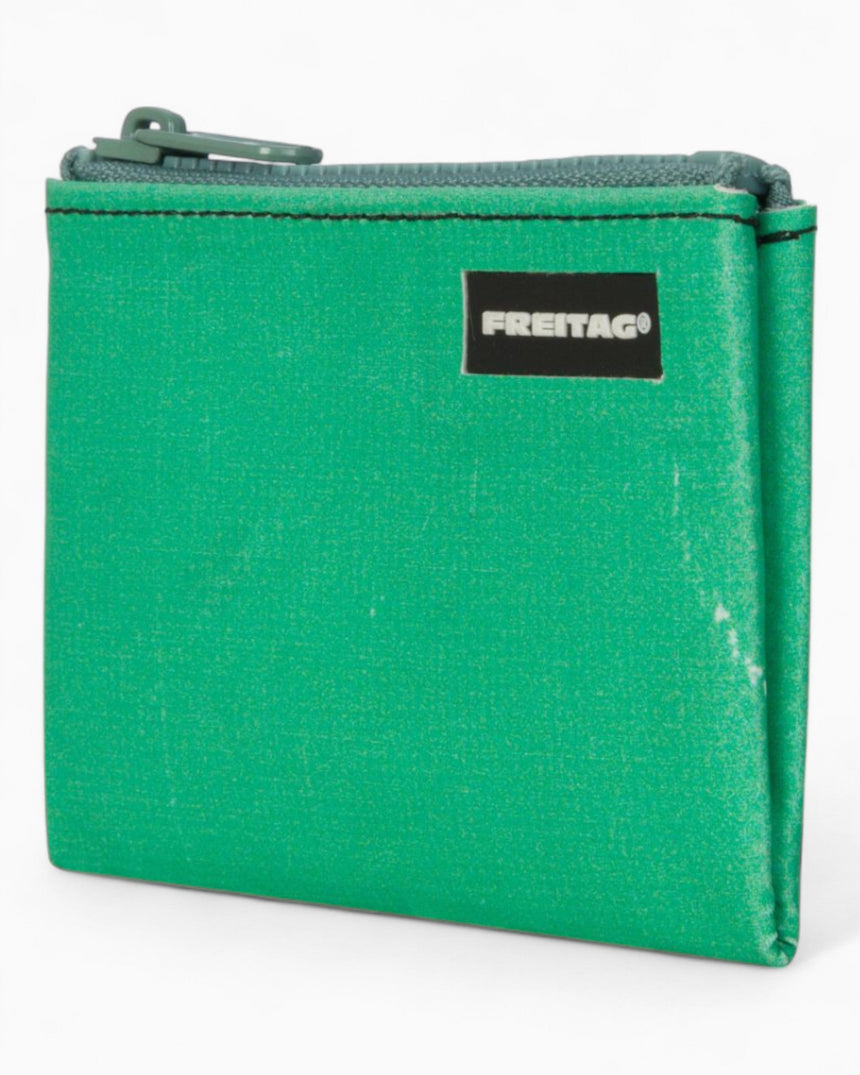

F05 Blair Wallet

Description

Description

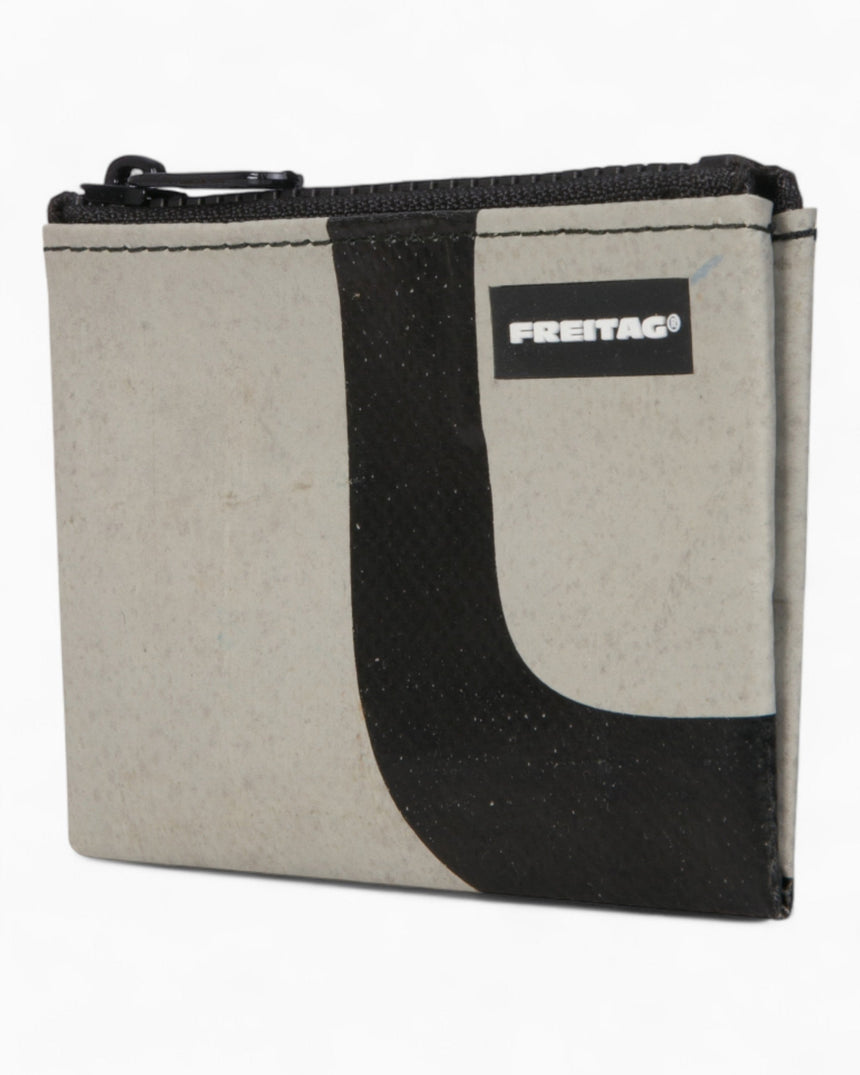

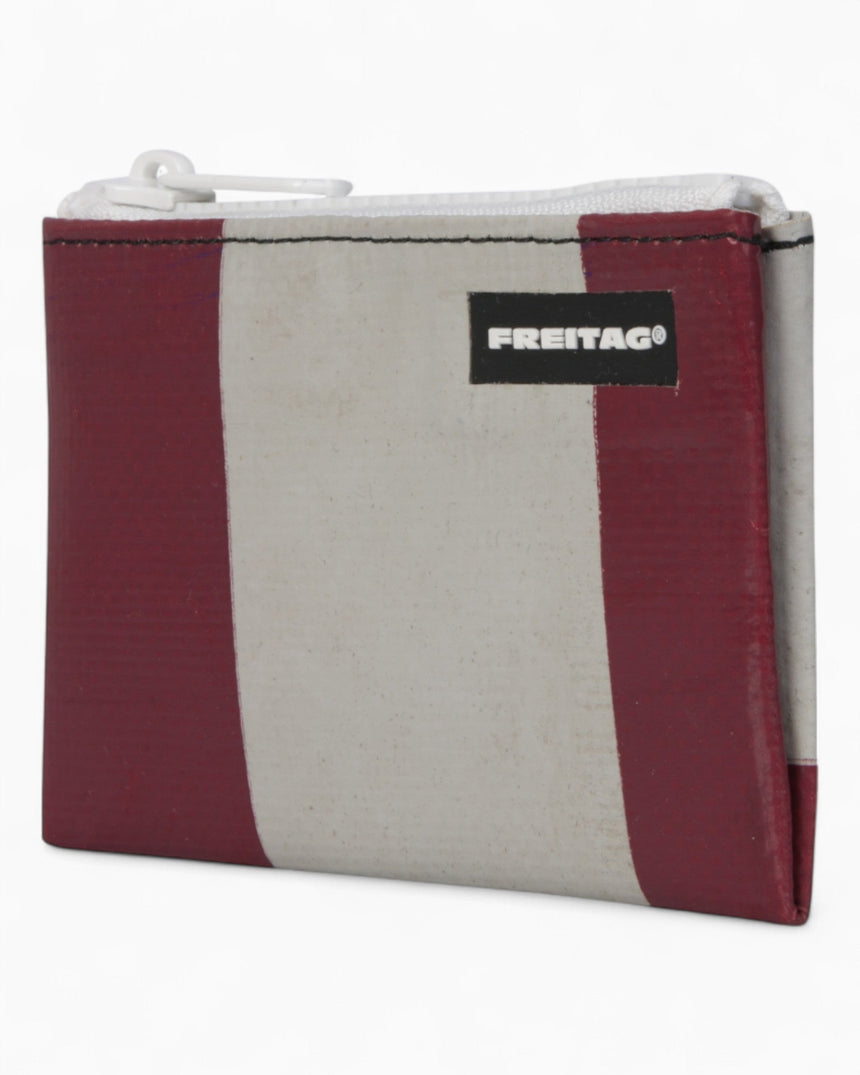

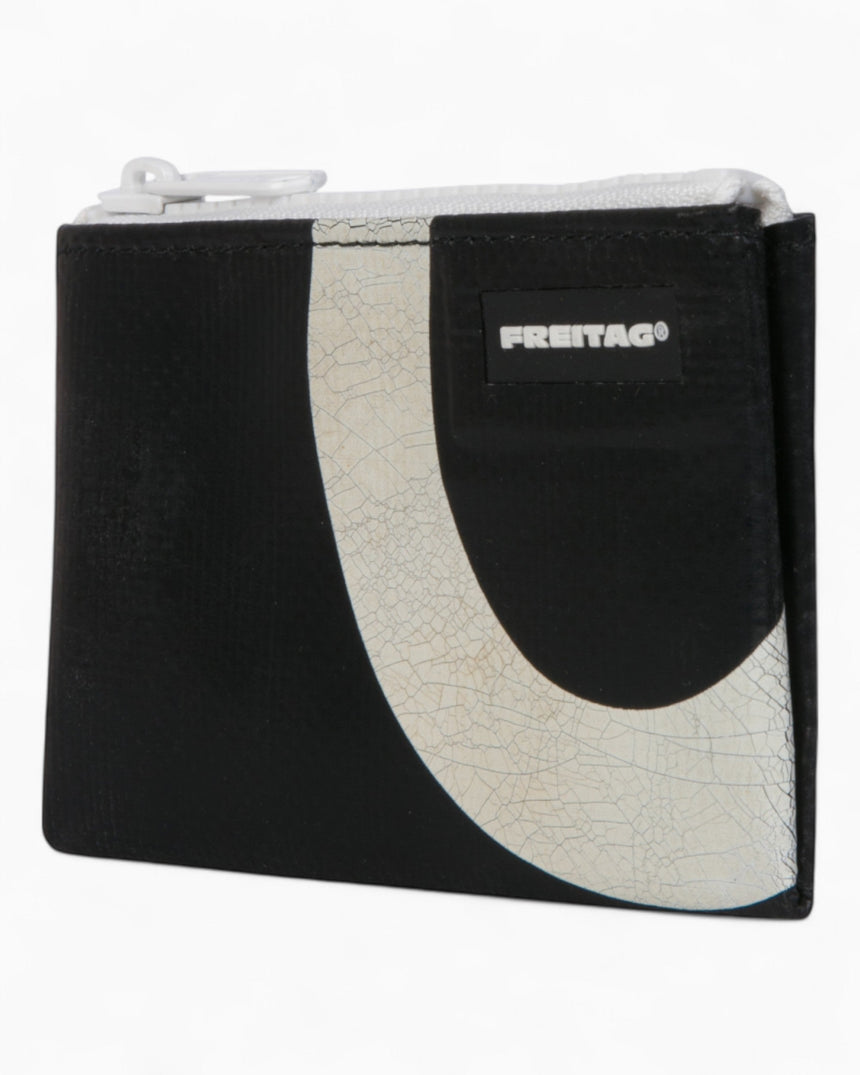

Blair - unique pouch made from used truck tarps. The pouch can be used as a wallet as well.

The smallest individual recycled pouch with colored zipper for small change, good coupons, tight hairpins, strangers’ business cards and anything else jingling in jacket and pant pockets.

For coins and any other bits and pieces that hide away at the bottom and back of the bag

- Material: used truck tarps (polyester fabric with PVC coating)

- Every pouch is unique

- Water-repellent upper

- Zip fastening

- Logo on the front

- Dimensions: 12.5 x 8.5 cm

- Weight: 40 g

- Place of Production: Romania

Marka Hakkında

Marka Hakkında

Teslimat ve Ücretsiz İade

Teslimat ve Ücretsiz İade

4.000 TL üzeri ücretsiz teslimat:

4.000 TL altı siparişlerde kargo ücreti 79 TL'dir. Siparişiniz aksi bir durum olmadıkça 1-2 iş günü içerisinde kargoya teslim edilir. Adresinize teslim süresi kargo şubelerindeki yoğunluğa bağlı olarak genellikle 1-3 iş günü arasında değişmektedir.

Ücretsiz iade:

Türkiye içinde iade işlemleri tamamen ücretsizdir. Teslim tarihinden itibaren 30 gün içerisinde, kullanılmamış, etiketleri sökülmemiş, yeniden satılabilirlik özelliği bozulmamış, aksesuarları eksiksiz olan ürünleri iade edebilirsiniz.

İstisnalar:

Kitaplarda ve iç giyim kategorisindeki alt ürünlerde iade yapılamamaktadır. Bikini&Mayo kategorisinde ise koruma bandı çıkarılmış ya da zarar görmüş ürünlerde iade yapılamamaktadır.